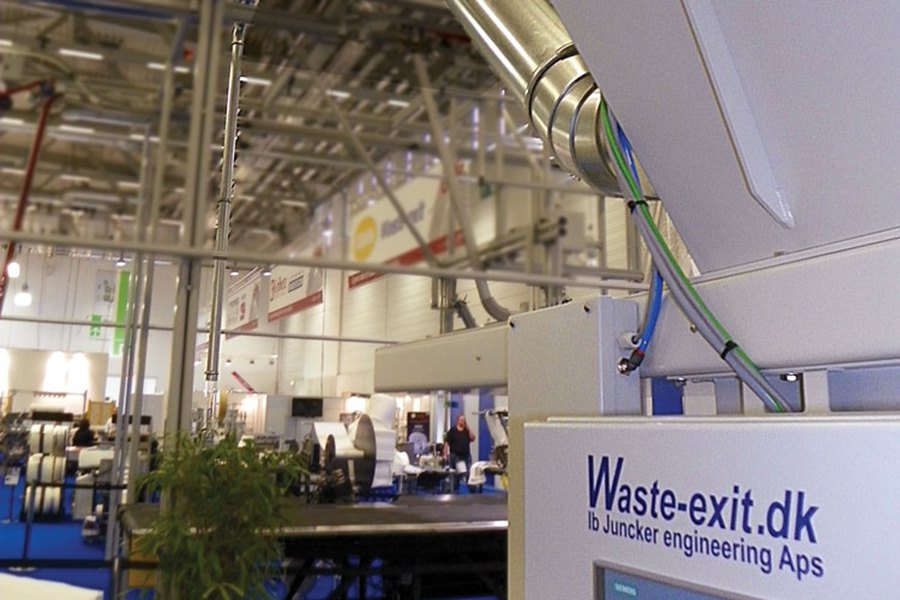

Waste-exit

This fully automated, vacuum-powered waste handling system from Waste-exit can dramatically improve your production efficiency and reduce worker injury hazards. Suction points can be added to any waste/dust-producing machine to automatically remove it from the work area and transport to a centralized collection point.

The Waste-exit clean factory system eliminates inefficient handling of scrap waste by automatically collecting, transporting, and depositing waste into an optimally positioned bin or baler.

Automatically moving scrap increases workcell efficiencies 10-30% and eliminates unnecessary labor. Waste-exit also removes 91% of airborne grit that destroys sewing equipment and computers.

Produces immediate impact on cost and efficiency with a typical ROI of 12-18 months.

- Eliminates non-value added handling of scrap and bulk waste

- Increases cell efficiencies 10-30%

- Eliminates trip-and-fall hazards around operator work space

- Captures machine and computer destroying airborne grit

- Dramatically reduces energy costs from over-working compressors in dirty environments

- Increases available factory floor space for improved workflow

- Reduces downtime and enables mechanics to better perform preventative maintenance

- Dramatically improves employee morale and attitude

*Productivity and efficiency claims listed here are based on typical industry scenarios. Every factory is unique, so your actual results may vary.

GSG Parts Catalog

Our catalog provides you with access to genuine Gribetz and Porter International mattress machinery parts. Using genuine parts helps reduce downtime and ensure a low-cost parts and service solution for the life of your machine.